Accessories and components

Catwalksand ladders for silos

To guarantee a superior quality finished product, at Ravaro Costruzioni Meccaniche we have developed some cereal monitoring systems

inside silos and processing plants. From ventilation, temperature and valve control to the supply of walkways and ladders, choose the quality of Ravaro brand systems.

Structures

Cyclones for dust suppression

Dust suppression cyclones perform the essential function of dust extraction and settling

produced inside the silos and cereal processing plants in order to guarantee a higher quality of the finished product.There design of these cyclones

today represents one of the strong points of the work at Ravaro Costruzioni Meccaniche, which has always paid attention to the quality of the products and the safety of personnel and the environment.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

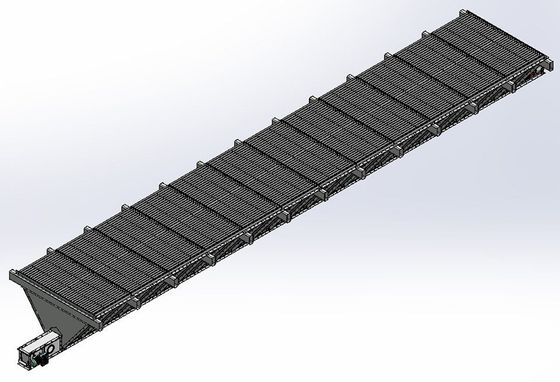

Walkways and stairs

Ravaro Costruzioni Meccaniche designs and produces in full compliance with safety solutions for access to various machinery and silos:

- ladders with cage;

- protective parapets;

- modular walkways.

Each system is designed to have accesses and dimensions that can be variable depending on the customer's needs. Robust and resistant to atmospheric agents, Ravaro brand solutions are built with the highest safety and quality standards and designed to last over time.

Two-way pneumatic valve

The two-way pneumatic valve is a device for controlling and regulating the start, stop, direction, pressure and passage of products coming from a pressurized container.It has the function of automatically intercept the flow

of the product distributed in the system through a ball shutter, keeping only the previously established quantity in circulation.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Ventilation systems for the bottom of the silos

There ventilation of the cereal inside the silo

its objective is to cool the cereal itself so as to keep it constantly at a temperature that keeps it in excellent condition, thus avoiding the formation of mold and the natural deterioration of the cereal product. Discover the characteristics of Ravaro systems and choose the solutions to operate in total safety, such as parapets, walkways and ladders.

Temperature detection and monitoring systems

As in the case of ventilation, to keep the product in excellent condition and avoid the formation of mould, it is necessary to be able to monitor the temperature

inside silos or warehouses for the storage of cereals and seeds.A rapid lowering of the temperature of the cereal blocks the proliferation of mould, toxins and bacterial flora and stops the development of insects, through a drastic reduction in the cereal's metabolism.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Ventilated cone for silos

The ventilated conical bottoms, in addition to ensuring simple and total emptying of the silos, allow for perfect isolation of the product from the ground

and complete ventilation of all the material inside. The ventilated cones can also be installed on existing silos. Modular product reception pits are also available.

Strada Per Vespolate, 6 - 28060 Granozzo Con Monticello (NO)

39 0321 55146 | ravaro@ravaro.it

VAT Reg No 09274640961 | Legal Information

| Privacy Policy and Cookie Policy

Opening hours

- Mon - Fri

- - -

- Sat - Sun

- Closed