Mechanisation

Conveyors and elevators for themovement and sorting of cereals

For it storage and transport of cereals, granular or floured, Ravaro Costruzioni Meccaniche has designed elevators capable of sorting the product, even in very large quantities, along different paths.

Accessories and components

Discover the various models of elevators and conveyors available and choose the one that best meets your needs.

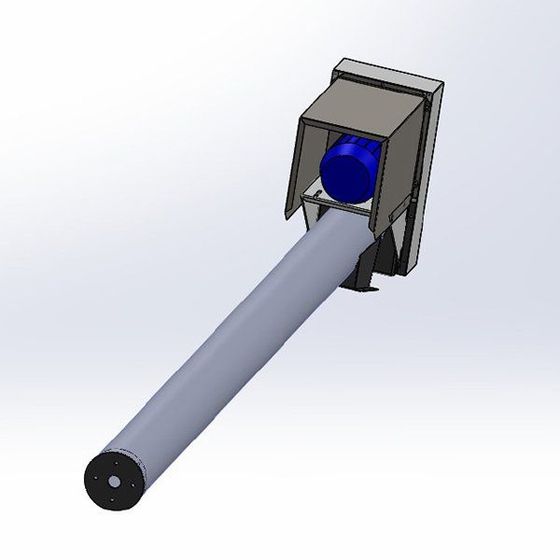

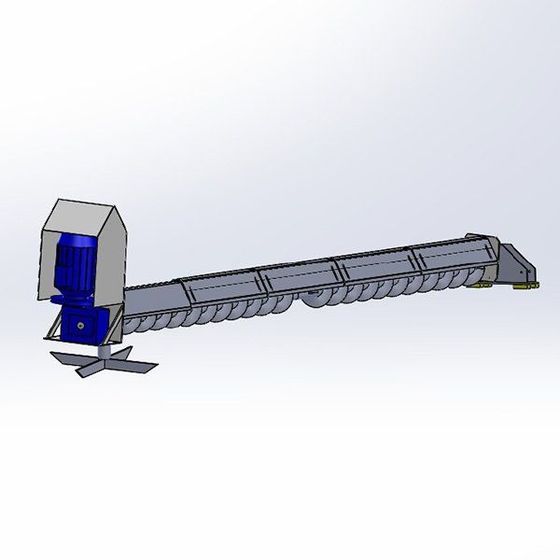

Screw conveyors

Tubular screw conveyors are suitable for transport of granular and flour products

on straight horizontal, inclined or vertical paths, and are created according to the needs and requirements specified by the customer.Ravaro Costruzioni Meccaniche offers screw, channel or tubular conveyors to achieve particularly high flow rates at low angular speed.

Request a quote

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Bucket elevatorsfor cereals

Grain bucket elevators are used for vertical transport of cereals

in granules, floured and diced. Ravaro Costruzioni Meccaniche produces bucket elevators up to 130 Ton/h which can also be equipped with anti-skid sensors and rotation controls. L'product elevation

takes place by means of cups mounted on a ring belt that runs inside modular elements in galvanized sheet metal. The product is loaded onto the foot of the elevator and unloaded from the head, thanks to the centrifugal speed of the belt.

Elevators technical characteristics

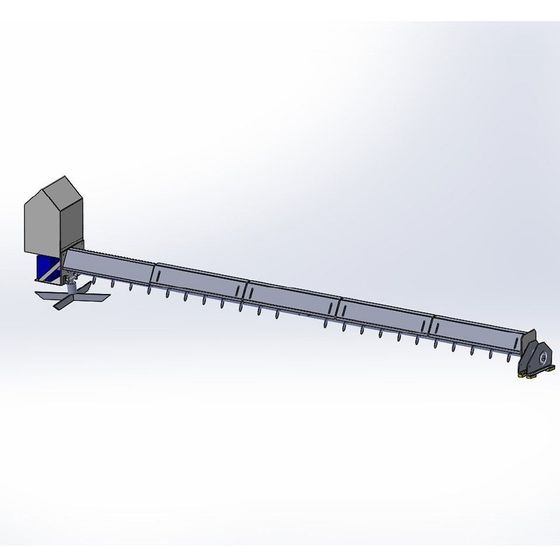

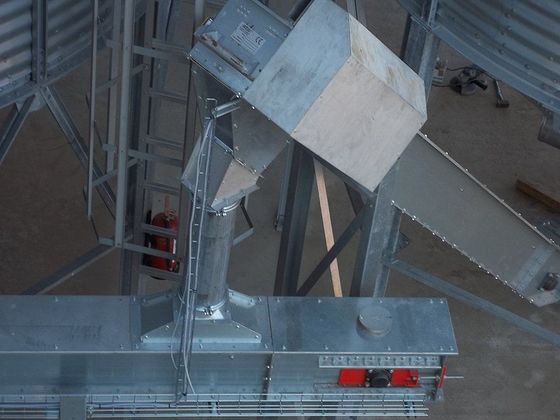

Rotary extractors

Rotary extractors are used for the unloading and emptying of the residual cone inside the silos

and can be activated through manual, semi-automatic and automatic operation.The rotary extractor allows the elimination of the residual cone by conveying the present product towards the center without the aid of operators.

The rotation of a mobile arm around the axis of the silo allows movement only after the auger, applied to the arm, has discharged all the cereal present.Depending on the size of the silo, the type of product, the discharge and the required flow rate, they are available various models of rotary extractors

which Ravaro Costruzioni Meccaniche designs based on the specifications of each individual system.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Cereal conveyor belts

Cereal belt conveyors are used in the transport of granular products

and floured on horizontal or slightly inclined paths, even of great length, and offer the advantage of requiring limited power and of not leaving residues inside the machinery (without breaking the transported product).

Ravaro Costruzioni Meccaniche designs conveyors

with sliding belt, cradle or slats for capacities from 25 tons/h to 200 tons/h.

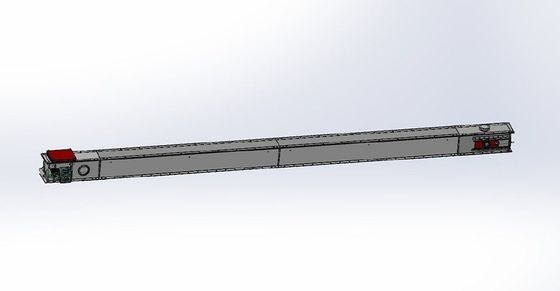

Chain conveyorsfor cereals

Grain chain conveyors are used, like belt conveyors, for the transport of granular and floured grains on long journeys and horizontal routes

or slightly inclined.Transport takes place inside a metal crate thanks to a scraping chain closed in a ring.Ravaro Costruzioni Meccaniche designs conveyors with C40 steel chain and nylon pallets.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Discover all the models of elevators and conveyors available:fill in the contact form

for a personalized quote

Contact us

Strada Per Vespolate, 6 - 28060 Granozzo Con Monticello (NO)

39 0321 55146 | ravaro@ravaro.it

VAT Reg No 09274640961 | Legal Information

| Privacy Policy and Cookie Policy

Opening hours

- Mon - Fri

- - -

- Sat - Sun

- Closed